Commercial Gear Racks

Commercial gear racks are made from 46S20 – C45 material from module 1 to module 6 and are always available from stock. Our racks are all butted for continuous assembly. On request we can produce standard racks but in special lengths.

Special Custom-made Racks

We can make any type of gear rack to customer design, with different precision and quality solutions to better meet the customer’s needs. We can supply the parts already heat and surface treated.

The production structure’s flexibility and cutting-edge technology allow the production of both individual pieces and large series.

Materials used in production are all certified and top quality:

– Carbon steel (C40-C45)

– Alloy steel for tempering and case hardening Tempered and hardened alloy steels

– Aluminium, bronze and brass alloys

– Stainless steel

– Plastics (Ertalon, Nylon, etc…)

Quality has always been a primary objective and is carefully monitored by qualified personnel from the first machining stages. The finished product is then checked in the testing department. Upon request, a certificate can be issued showing sizes, the material used, and the heat treatments carried out.

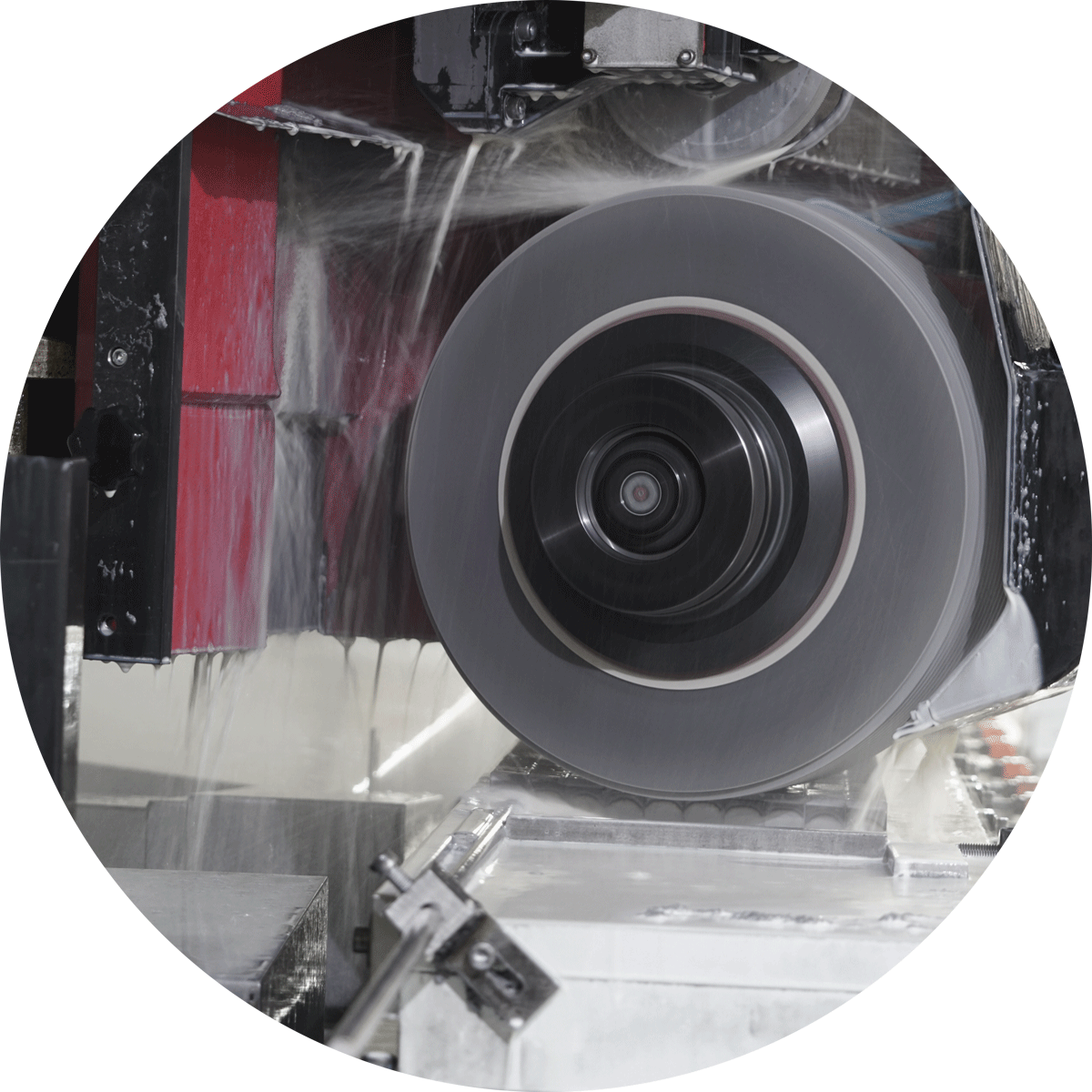

Third party machining

GFM performs gear rack toothing and grinding operations on material supplied by the customer.

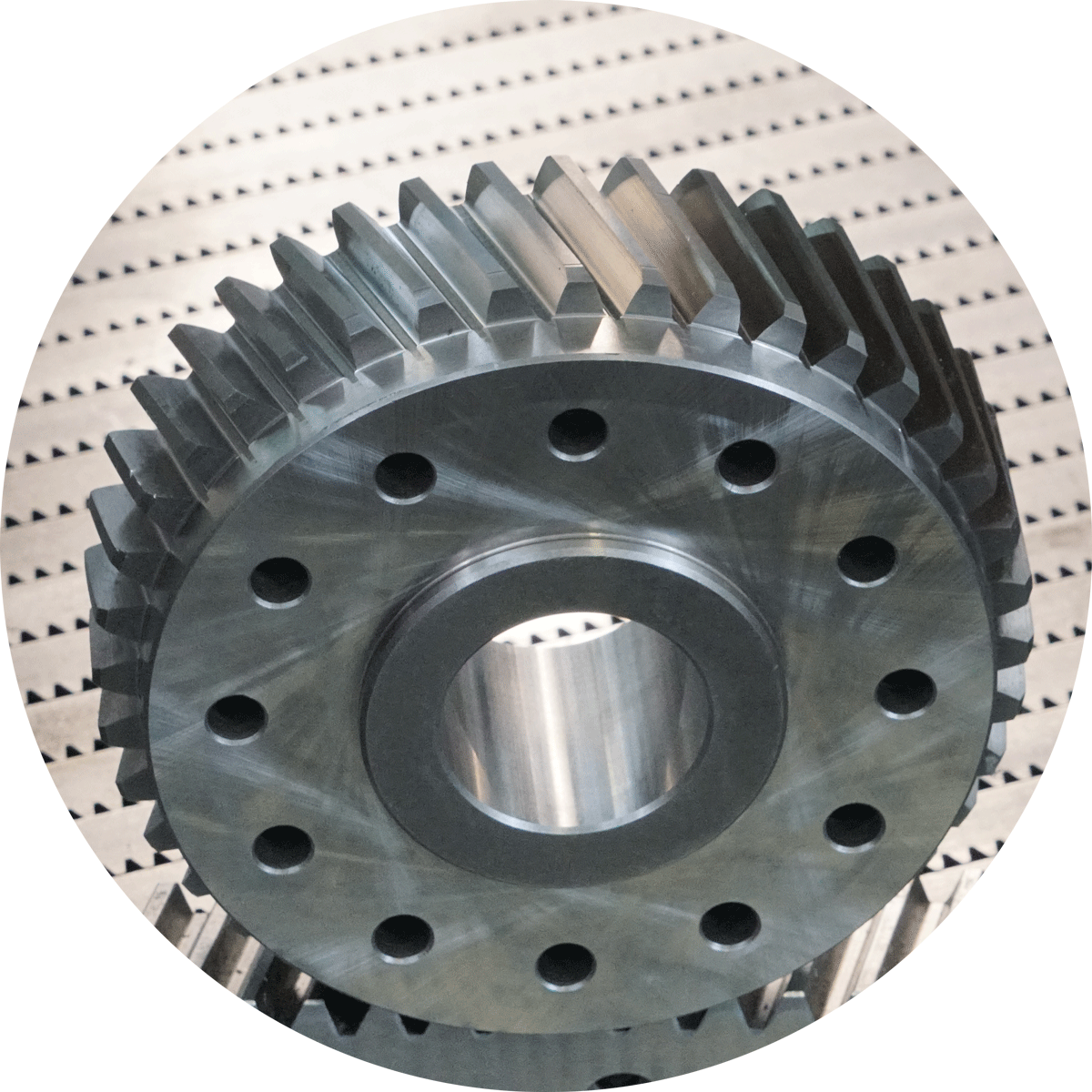

Made-to-measure gears

Thanks to the experience gained and the fruitful cooperation with selected and specialized external companies, we can also make gears based on the customer’s design, both for single pieces and for small and medium-sized series. The gears can be supplied complete with heat and surface treatment, and profile grinding.

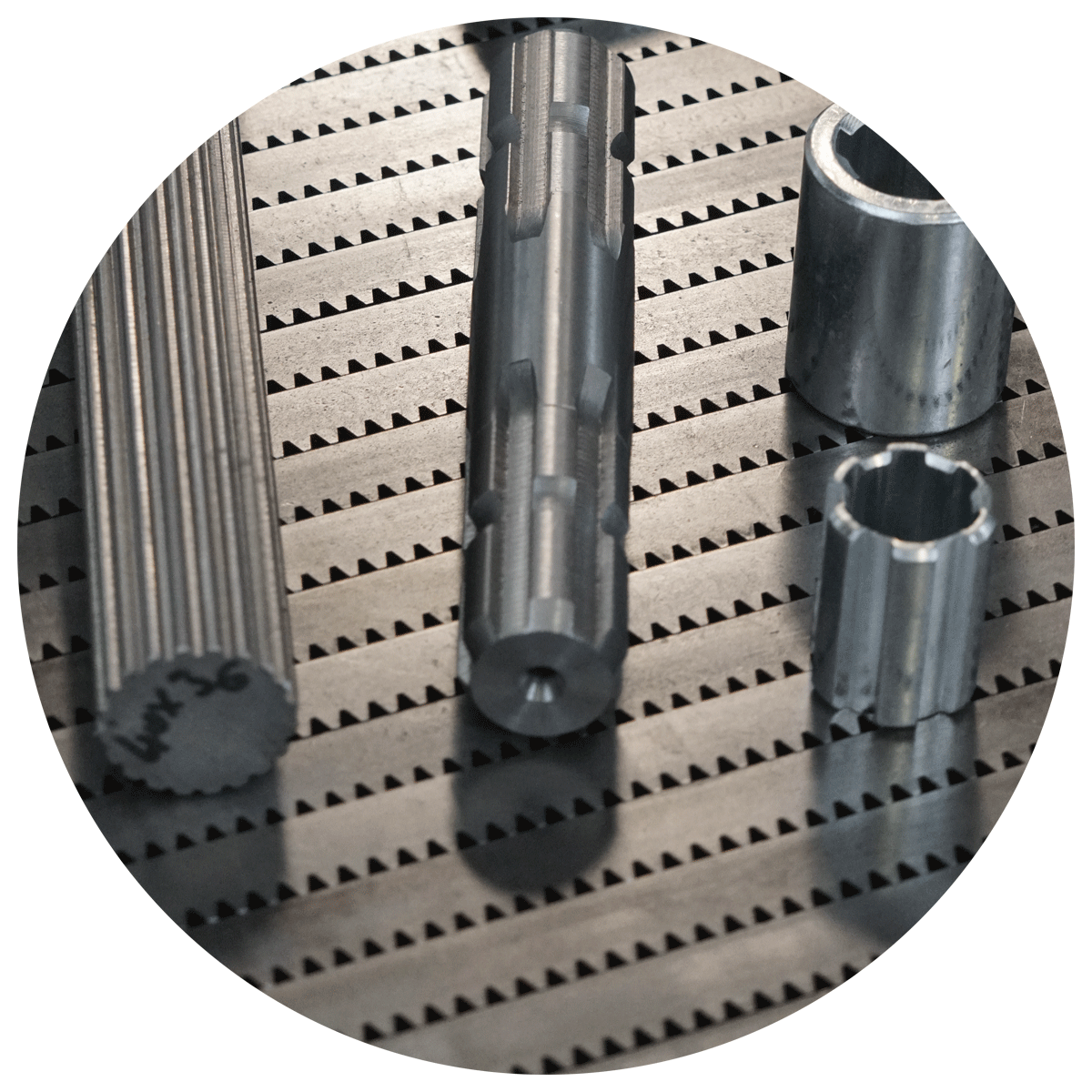

Grooved bars

GFM’s grooved bars are produced from extruded C45 material and are available from stock in lengths up to 4000 mm. Upon customer request, we can cut to size without any surcharge.

Grooved Bushes

Produced from C45 material, they are available in these profiles:

UNI 221: from 11×14 to 46×54

UNI 220: 26×30

DIN 5482

SAE 9611: 1”1/8 – 1”3/8 – 1”3/4

In addition to the standard production, we can make special parts to the customer’s design.

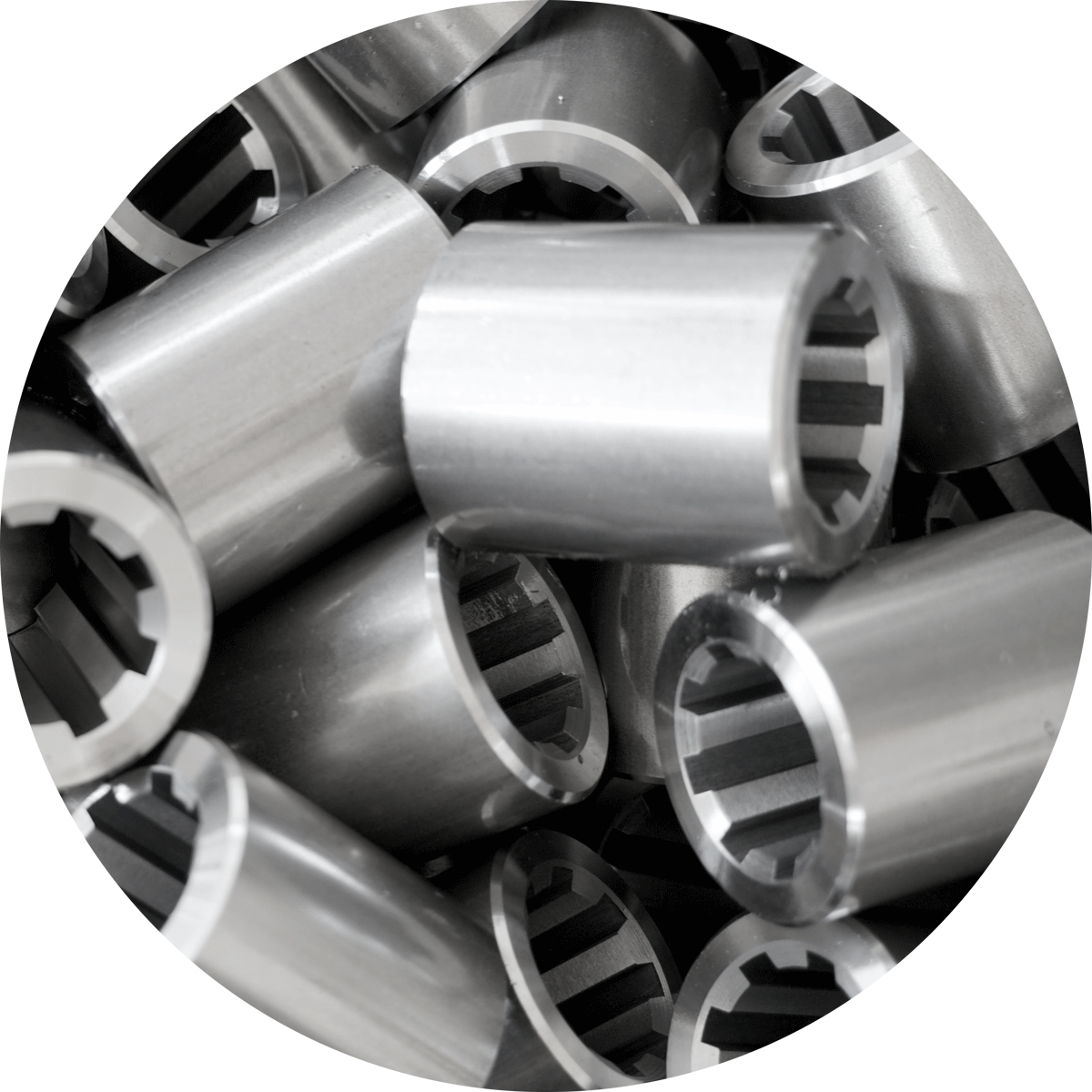

Accessories for agricultural machinery take-offs

GFM Meccanica’s catalogue is extensive and constantly evolving, to rightly follow the customer’s changing needs: the experience and professionalism nurtured over the years have allowed the acquisition of a precise operational know how, which led the company from Reggio Emilia to be a point of reference in the production of agricultural machinery power take-off accessories, all guaranteeing particularly high quality and precision standards. Many models and versions are available: for this reason, the staff of GFM is at the service of the customer to guarantee the certainty of quickly identifying the most suitable product every time. To know the detailed availability of the articles, you can contact the company.

In addition to the standard production, we can make special parts to the customer’s design.